con Rótulas

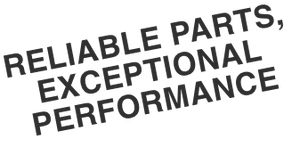

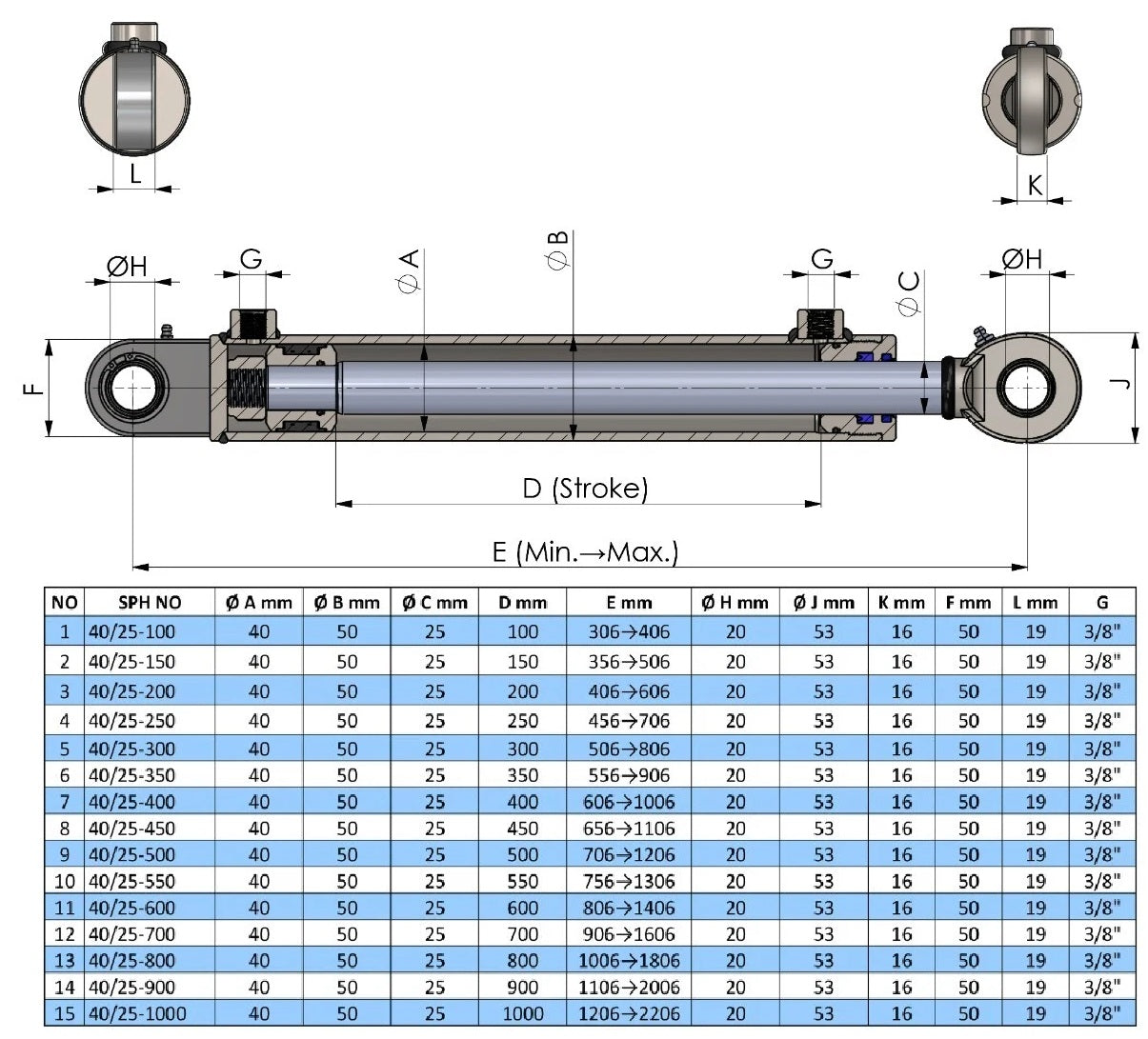

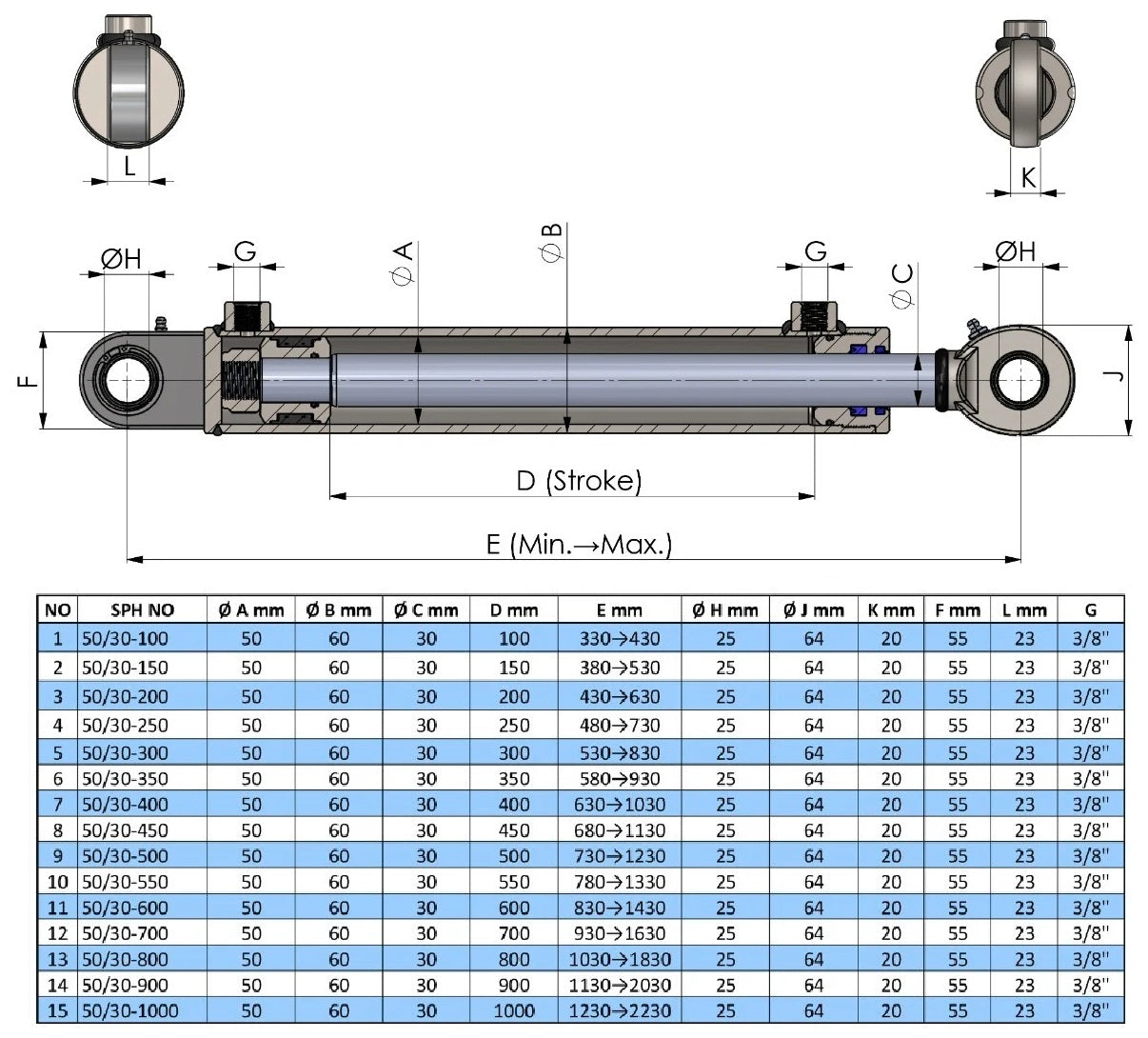

Double Acting Hydraulic Cylinders with Ball Joint Mountings

This collection includes double acting hydraulic cylinders with ball joint mountings, designed for hydraulic applications where controlled pushing and pulling force is required while allowing angular movement at the mounting points.

The ball joint mountings, also referred to as spherical joints or spherical bearing mountings, enable the cylinder to compensate for misalignment during operation. This reduces side loads on the piston rod and ensures smooth, reliable movement in demanding applications.

Typical Applications

Double acting hydraulic cylinders with ball joint mountings are used in agricultural, industrial, transport, and mobile hydraulic systems where movement is not perfectly linear.

- Agricultural machinery and implements with varying working angles

- Loaders and lifting mechanisms subject to frame or chassis movement

- Trailer and transport equipment requiring articulated motion

- Industrial machines where alignment changes under load

Ball Joint (Spherical Bearing) Mountings Explained

The ball joint mounting consists of a spherical bearing integrated into the cylinder end. This allows controlled rotational movement, reduces stress on mounting points, and minimises wear compared to rigid end connections.

Construction and Reliability

All double acting hydraulic cylinders with ball joint mountings are manufactured from high-quality steel and equipped with chrome-plated piston rods to reduce wear and corrosion. Durable sealing systems ensure leak-free operation and consistent performance in agricultural, industrial, and mobile environments.

Related Hydraulic Cylinders

If you are looking for hydraulic cylinders specifically designed for steering or power steering systems, these are available in a dedicated steering cylinder collection on our website. Steering applications require cylinder designs matched to steering geometry and operating characteristics.

Select the Correct Hydraulic Cylinder

Select the appropriate cylinder based on bore size, stroke length, ball joint dimensions, and operating conditions. Each product page provides detailed technical specifications to ensure correct selection and safe operation.