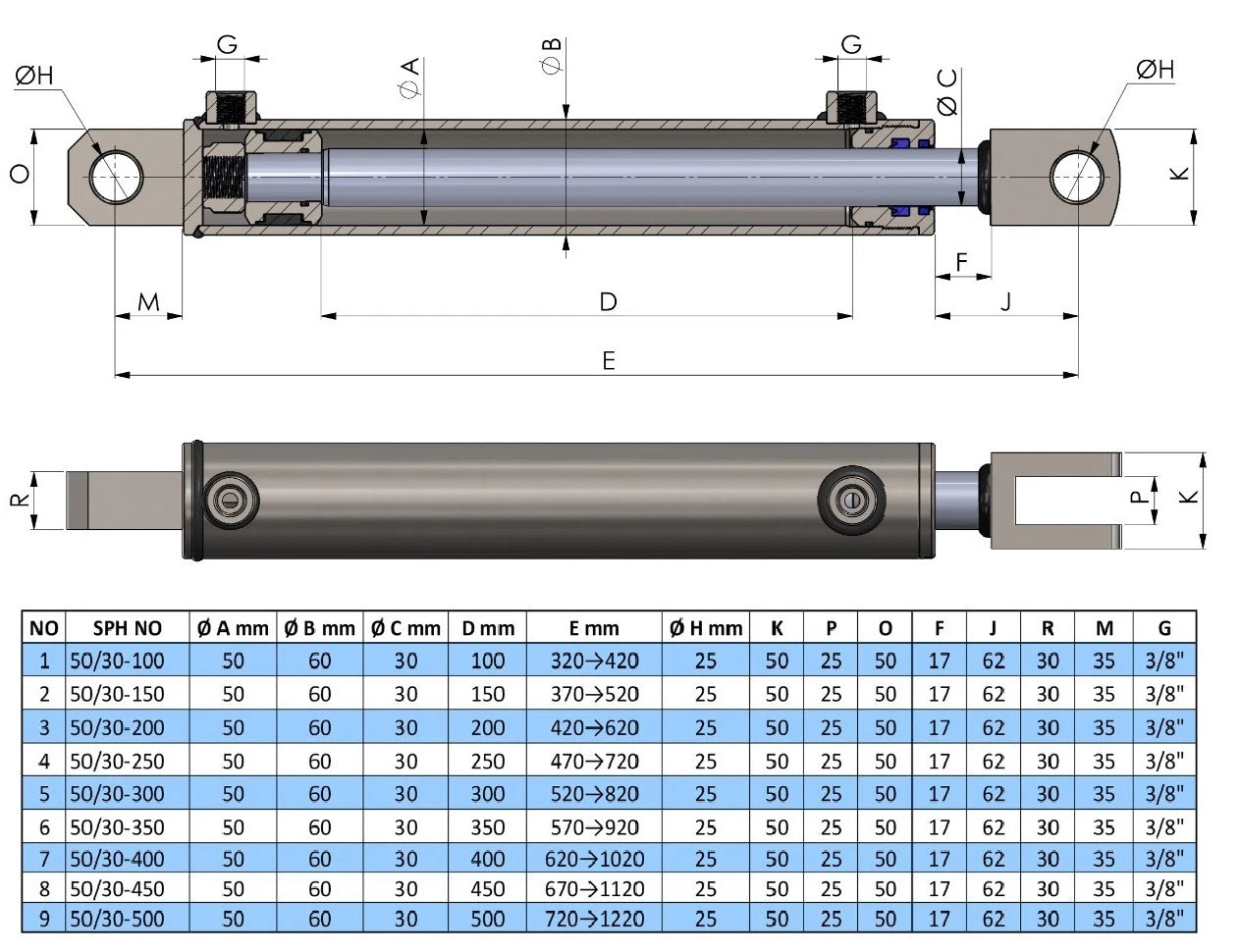

Clevis and Fork

Double acting hydraulic cylinders with clevis and fork mountings for agricultural and industrial use

Double Acting Hydraulic Cylinders with Clevis and Fork Mountings

This collection includes double acting hydraulic cylinders with clevis and fork mountings, designed for hydraulic applications that require controlled pushing and pulling force combined with a strong, pin-mounted connection.

Clevis and fork mountings provide a stable and proven solution for linear hydraulic movement, allowing controlled pivoting around the pin while maintaining a rigid connection. This makes these cylinders suitable for force-driven applications where alignment remains largely fixed during operation.

Typical Applications

Double acting hydraulic cylinders with clevis and fork mountings are widely used in agricultural, industrial, and mobile hydraulic systems where reliable push–pull force and secure pin connections are required.

- Agricultural machinery and implements for lifting, folding, and adjustment

- Trailers and transport equipment with pin-mounted hydraulic functions

- Industrial machinery requiring controlled linear movement

- General hydraulic systems with fixed mounting geometry

Clevis and Fork Mountings Explained

The clevis and fork mounting consists of a U-shaped fork or clevis end designed for pin connection. This mounting type allows rotation around the pin axis, reduces stress on mounting points, and provides a durable connection suitable for heavy-duty hydraulic applications.

Construction and Reliability

All double acting hydraulic cylinders with clevis and fork mountings are manufactured from high-quality steel and fitted with chrome-plated piston rods to reduce wear and corrosion. Durable sealing systems ensure leak-free operation and consistent performance in demanding agricultural and industrial environments.

Related Hydraulic Cylinders

If your application requires greater angular compensation at the mounting points, hydraulic cylinders with ball joint (spherical bearing) mountings are available in a separate collection on our website.

Select the Correct Hydraulic Cylinder

Select the appropriate cylinder based on bore size, stroke length, clevis or fork dimensions, pin diameter, and operating conditions. Each product page provides detailed technical specifications to ensure correct selection and safe operation.